Dexko Global

Boat Trailers

Parts, Kits & Accessories for Boat Trailers

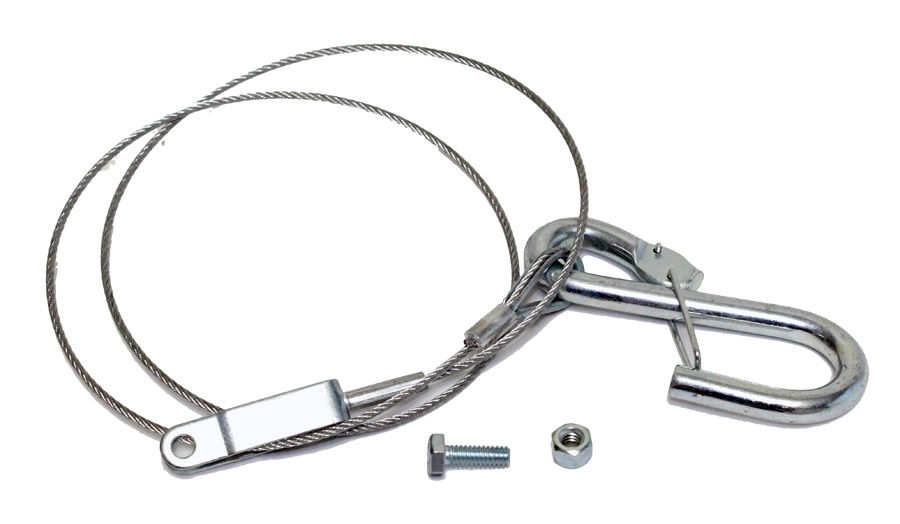

Keep your boat trailer ready for the road with quality parts. From axles and hubs to springs, tires, and brakes, we have everything you need to tow safely and confidently to the water and back.

Fast shipping

OEM-trusted brands

Tech resources

Shop Popular Categories

Axle Assemblies

Tires & Wheels

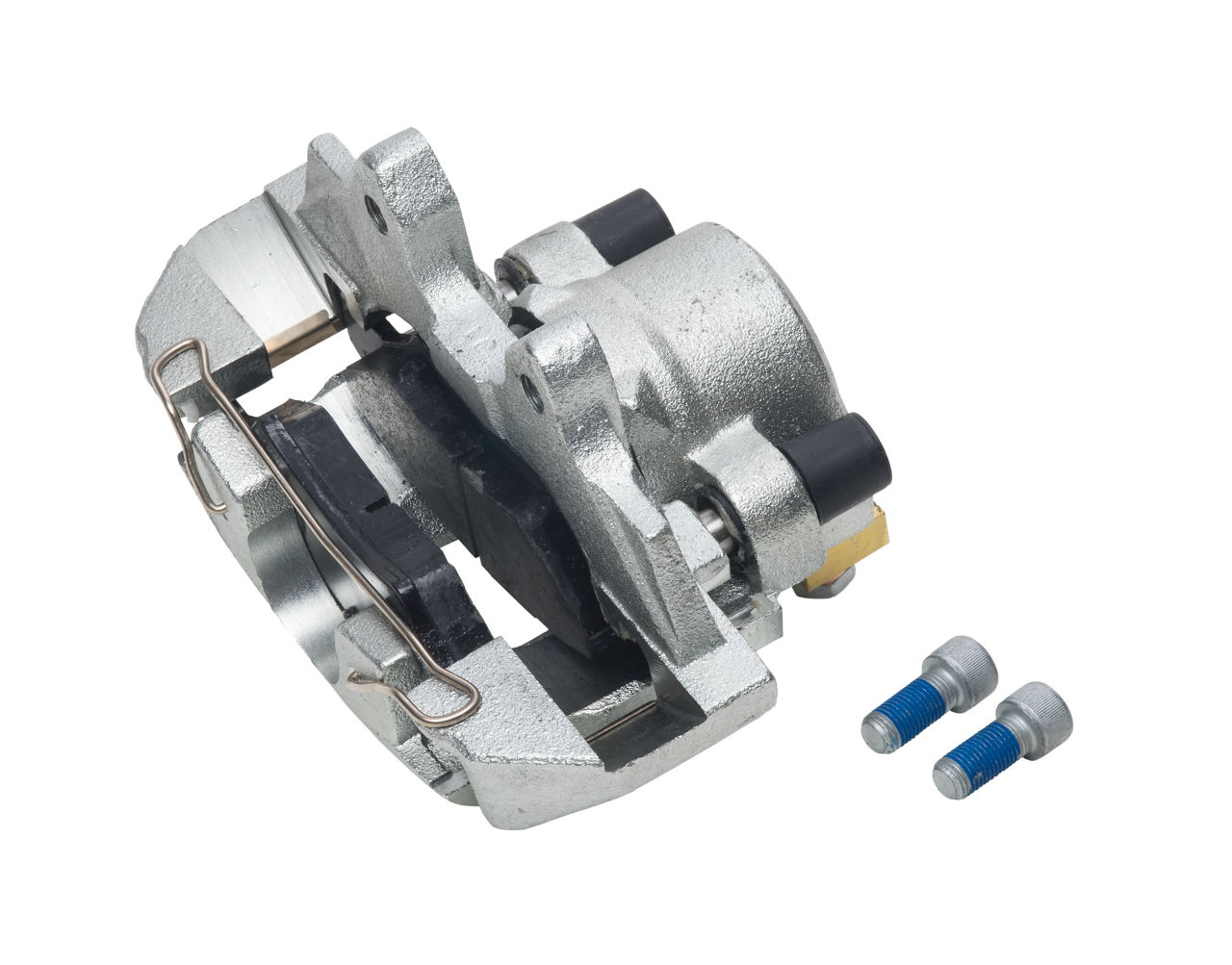

Boat Trailer Brake Assemblies

Boat Trailer Axle Components

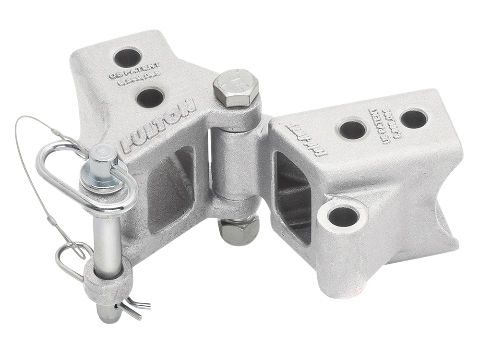

Boat Trailer Couplers

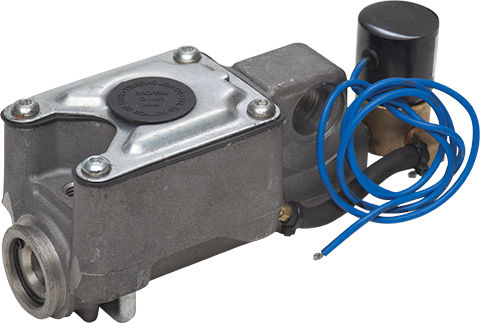

Boat Trailer Actuators

Boat Trailer Jacks

Boat Trailer Winches

Boat Trailer Locks

Boat Trailer Suspension

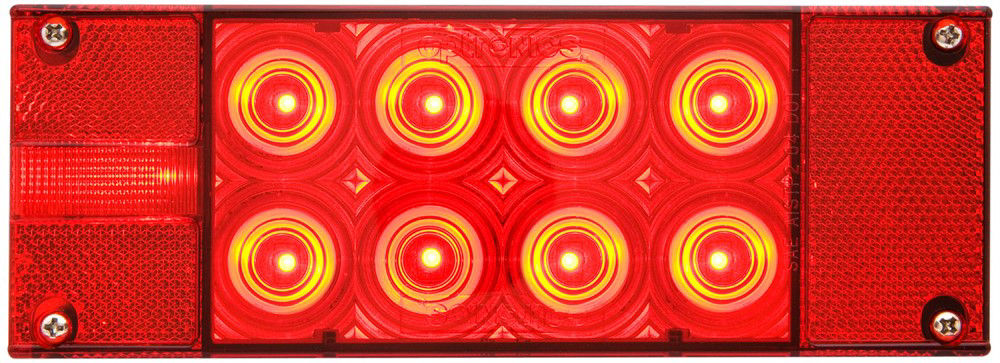

Boat Trailer Lighting

Boat Trailer — Overview

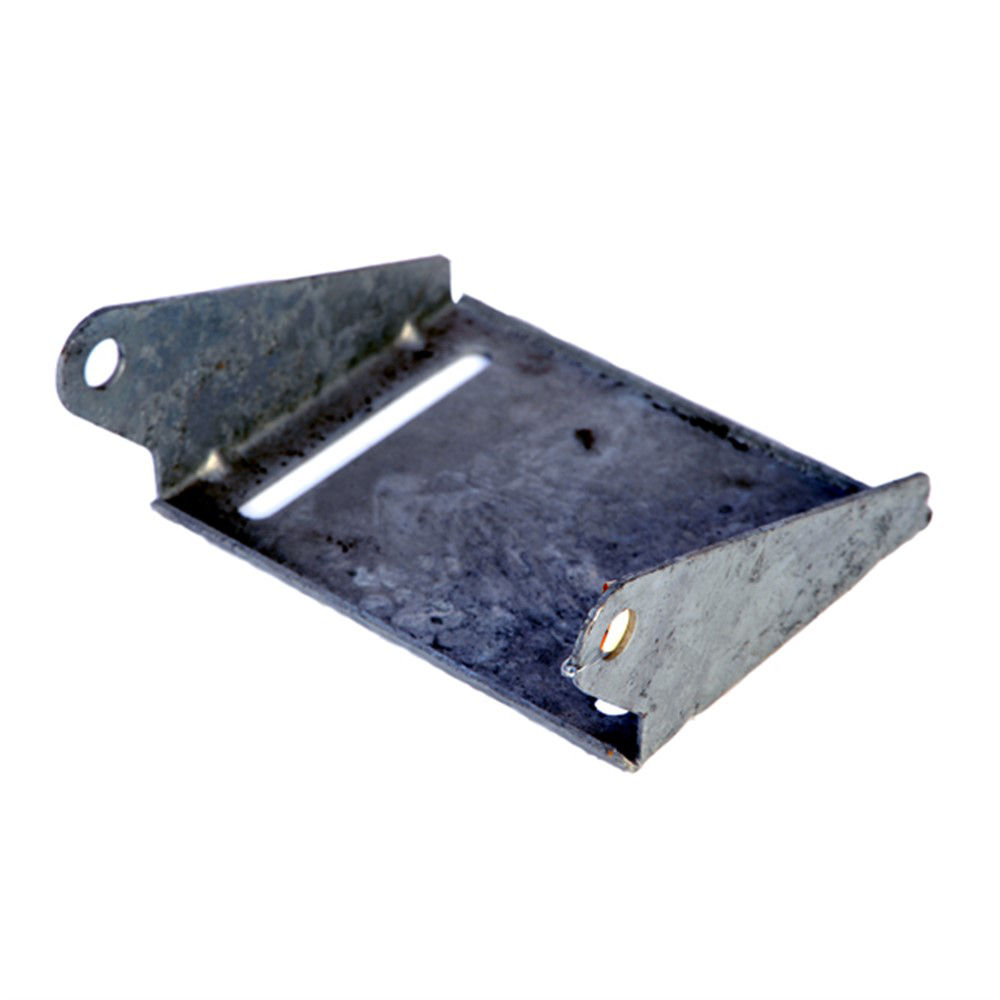

Dexter builds boat trailer systems for the water environment, focused on long life, ease of use, and serviceability. Options include galvanized, zinc-plated, or powder-coated finishes on axles and hardware, with components engineered for reliable launch and retrieval.

Marine axles are built to order in torsion or leaf-spring configurations including optional drop center variations. Pair with surge brake actuators, hydraulic drum or disc brakes, and sealed/underwater-rated lighting for dependable performance season after season.

Common Marine Applications

Pontoons & deck boats

Fishing & bass boats

Personal watercraft (PWC) & jet skis

Runabouts & inshore craft

Spec & Setup Tips

Choose torsion or leaf-spring axles to match ride and load.

Select galvanized, zinc-plated, or powder-coated finishes for corrosion resistance.

Match surge actuator with hydraulic drum or disc brakes.

Marine Maintenance

Rinse brakes, hubs, and hardware after saltwater use.

Use marine grease; inspect bearing protectors before the season.

Check winch straps and rollers for wear; replace if frayed/cracked.

Lighting & Wiring

Use sealed, submersible LED lamps and protect runs with loom.

Verify grounds—most lighting issues start there.

Add conspicuity/marker lighting for visibility at the ramp.

Boat Trailer FAQs

Need Assistance? Reach out to us:

Call Us:

- Swift Current: 855-778-7302

- Longueuil: 866-767-4867

- Brantford: 833-753-0013

- Milton: 877-876-3344

Email: canada@dextergroup.com