Dexko Global

Dump Trailers

Parts, Kits & Accessories for Dump Trailers

Keep your dump trailer running strong with high-quality replacement quality parts built for performance and durability.

Fast shipping

OEM‑trusted brands

Tech resources

Shop Popular Categories

Choose a parent category on the left; browse focused sub-categories on the right.

Axle Assemblies

Tires & Wheels

Dump Trailer Hydraulics

New products coming soon

Coming Soon!

Boxed Pump Units

Coming Soon!

Pumps

Coming Soon!

Cylinders

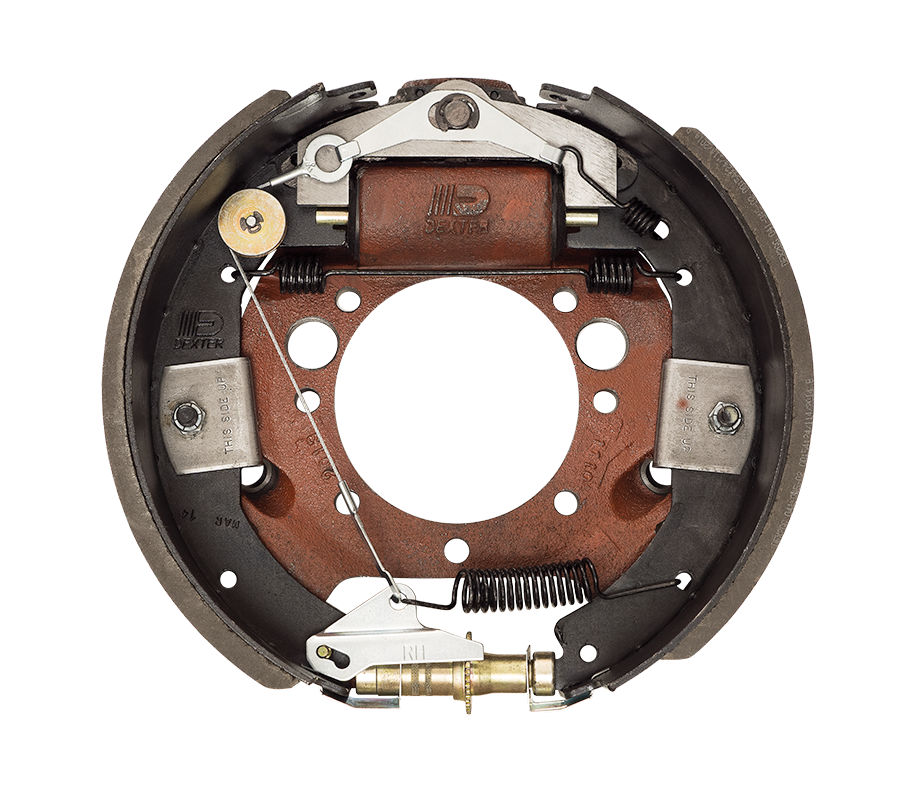

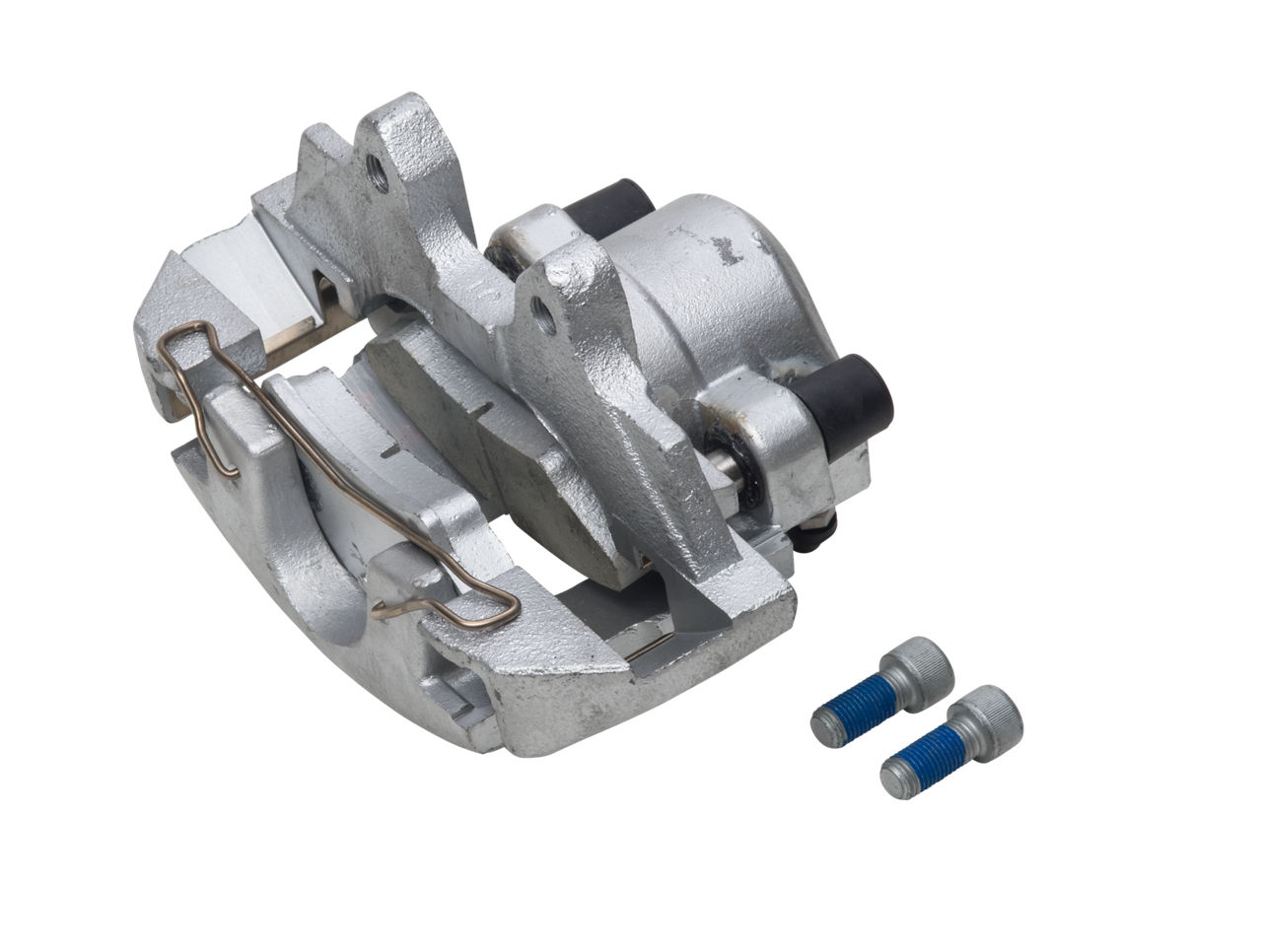

Dump Trailer Brake Assemblies

Dump Trailer Axle Components

Dump Trailer Couplers

Dump Trailer Jacks

Dump Trailer Breakaway Systems

Dump Trailer Suspension

Dump Trailer Body Components

Dump Trailer Electrical

Dump Trailer Lighting

Dump Trailer Chain & Hardware

Reliable & Durable

Dexter has been a trusted trailer component manufacturer for over 60 years. We manufacture high-quality axles designed and rigorously tested by our team of experts. Dexter’s axle capacities range from 2,000lbs to 16,000lbs. You can have confidence in your trailer when it is supported by an industry leader.

Common Applications

Construction & Demolition — hauling & unloading heavy debris

Landscaping — transporting soil, mulch, gravel, and other bulk materials

Agriculture — moving grain, feed, and fertilizer

Waste & Scrap Removal — hauling junk, scrap, and recyclables

Home & Commercial Projects — outdoor work, driveways, renovations

How to Measure Your Axle

The most common industry measurement is Hub Face, which is the measurement from the wheel mounting surface on one hub to the wheel mounting surface of the opposite hub.

Spring centers are the centerline measurement of the spring mounting pads on the axle.

Lighting & Wiring Tips

Use tinned copper connectors & heat-shrink.

Protect runs with loom & grommets.

Verify grounds — most lighting issues start there.

Bearing Maintenance Tips

Along with bearing adjustment, proper lubrication is essential to the function and reliability of your trailer axle. Bearings should be lubricated every 12 months or 12,000 miles.

Dump Trailer FAQs

Need Assistance? Reach out to us:

Call Us:

- Swift Current: 855-778-7302

- Longueuil: 866-767-4867

- Brantford: 833-753-0013

- Milton: 877-876-3344

Email: canada@dextergroup.com