Dexko Global

Flat Deck Trailers

Parts, Kits & Accessories for Flat Deck Trailers

Maintain your flat deck trailer with tough, reliable parts. From axles and brakes to tie-downs and decking, we’ve got what you need for performance and durability on every haul.

Fast shipping

OEM-trusted brands

Tech resources

Shop Popular Categories

Axle Assemblies

Tires & Wheels

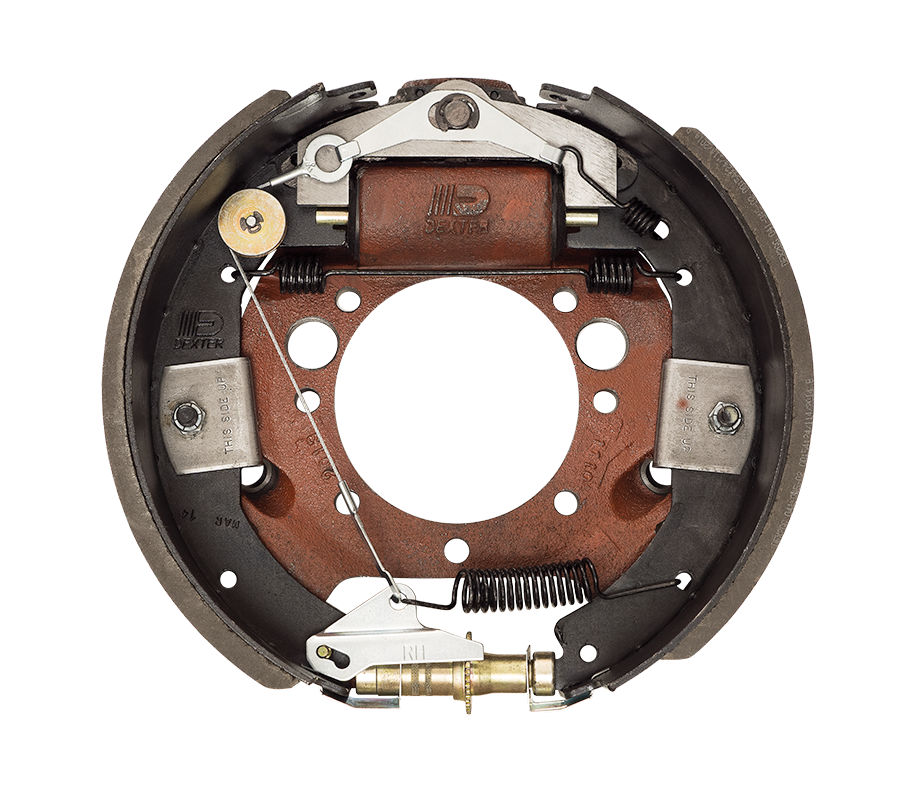

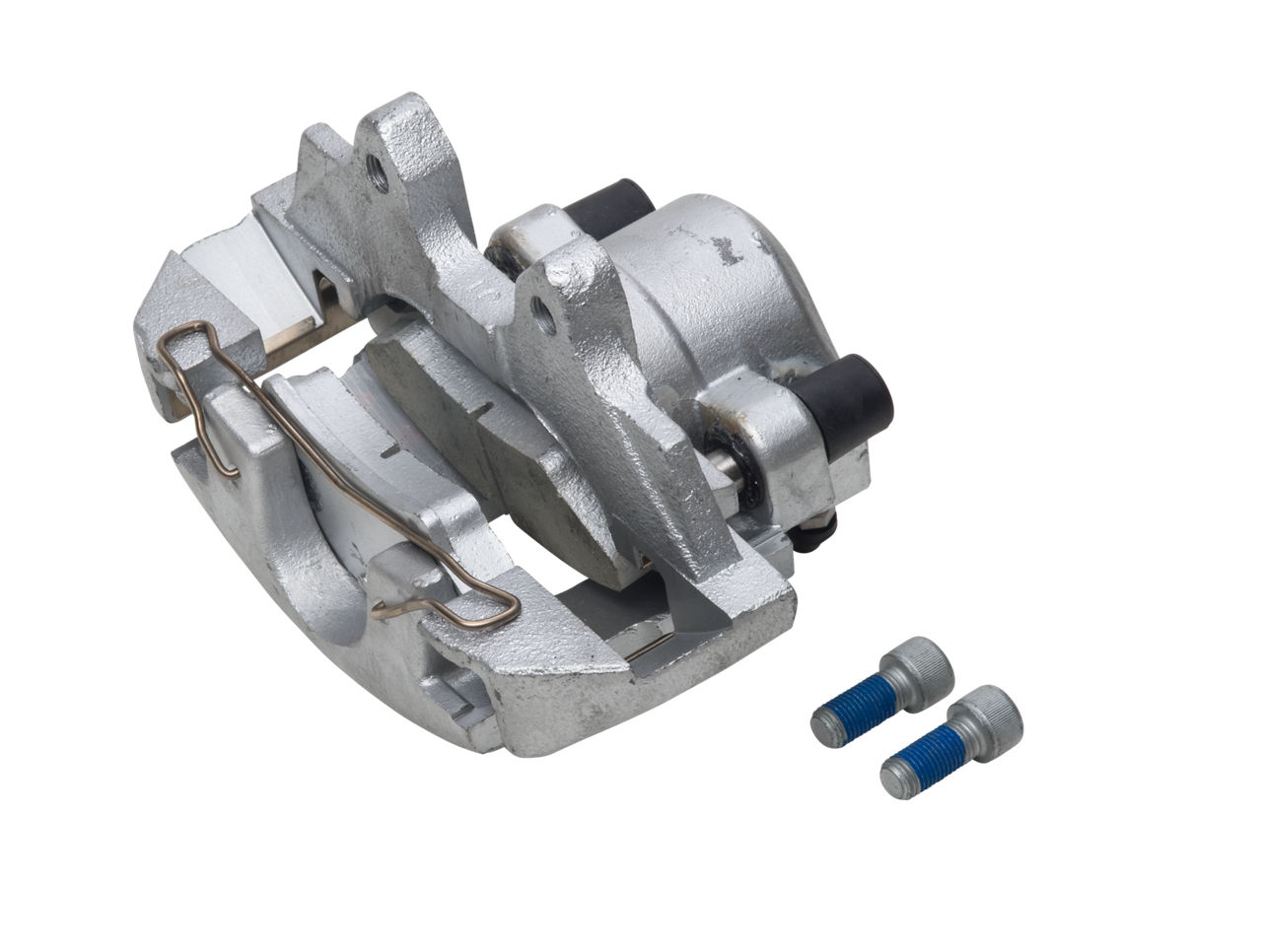

Flat Deck Brake Assemblies

Flat Deck Couplers

Flat Deck Jacks

Flat Deck Breakaway

Flat Deck Brake Actuators

Flat Deck Suspension

Flat Deck Lighting

Flat Deck Chain & Hardware

Flat Deck Cargo Control

Flat Deck — Overview

Dexter is an industry leader in safe, reliable trailer components, with 60M+ axles produced since 1960 . For commercial-grade and heavy-duty flat decks, Dexter systems cover robust, quality axle assemblies, brakes, suspensions, wheels/tires, landing gear, couplers, lighting, and securement accessories engineered for uptime in demanding fleets.

Customizable solutions are available across general utility and heavy-duty industrial applications so you can spec the right running gear for your deck, payload, and duty cycle.

Common Flat Deck Applications

Construction materials — lumber, steel, panel goods, pipe

Machinery & equipment transport (skids, generators, small dozers)

Palletized freight & crated goods

Farm & ranch — implements, feed, fencing

Industrial haulage — plate, bar, coil, and yard transfers

Spec Tips: Running Gear

Match axle rating & suspension to gross payload and duty cycle

Consider Electric/Hydraulic brake actuation paired with Duo-Servo hydraulic drum brakes for superior stopping capability

Inner tubes of Gooseneck couplers can be replaced with Kingpin style models allowing use of your existing 5th wheel hitch

Cargo Securement Basics

Review working load limits on your webbing and chain to ensure your loads are safe and secure

Consider 3-bar style webbing winches for superior performance in the winter season

Re-check tension after the first few miles and at each stop

Lighting & Wiring Tips

Use tinned-copper connectors with heat-shrink; protect runs with loom

Confirm solid grounds — most lighting issues start there

Add conspicuity tape and side markers for long loads

Flat Deck Trailer FAQs

Need Assistance? Reach out to us:

Call Us:

- Swift Current: 855-778-7302

- Longueuil: 866-767-4867

- Brantford: 833-753-0013

- Milton: 877-876-3344

Email: canada@dextergroup.com